Why Silent Diesel Generators Matter in Commercial Settings

The Importance of Noise Reduction in Workplaces and Public Spaces

Excessive noise in commercial environments reduces productivity by up to 40% (Occupational Health Journal 2023) and violates municipal noise ordinances in 68% of urban districts. Silent diesel generators maintain sound levels below 75 dB—quieter than standard office chatter—making them ideal for schools, hospitals, and corporate campuses where uninterrupted focus is essential.

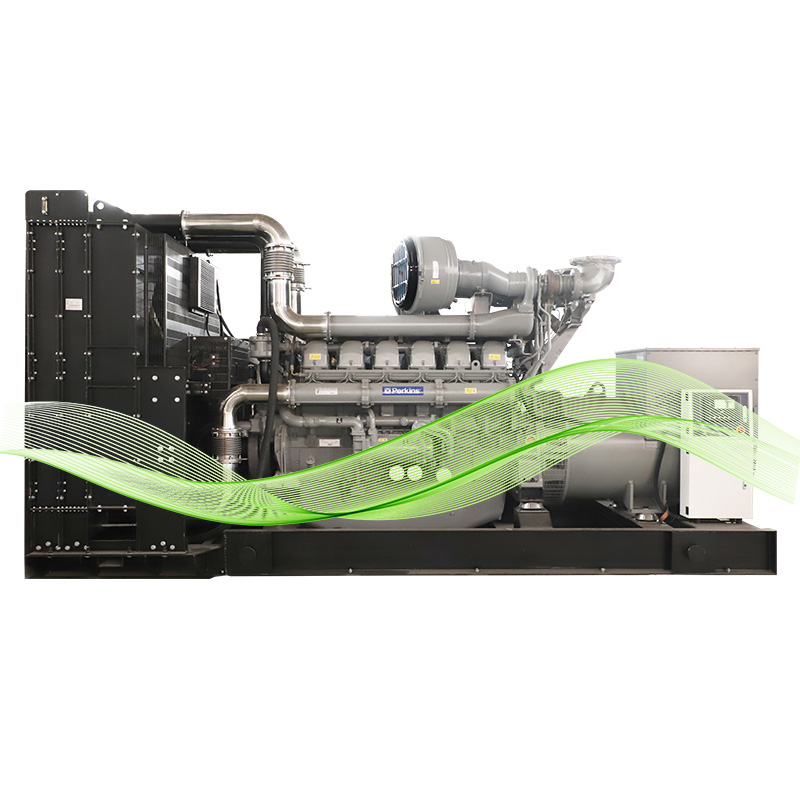

How Silent Diesel Generator Technology Achieves Low Sound Emissions

Advanced engineering integrates three noise-suppression layers:

- Acoustic Enclosures: Absorb 60–70% of mechanical noise through steel-composite panels.

- Vibration Dampeners: Isolate engine movements to prevent structural resonance.

- Exhaust Mufflers: Reduce combustion noise by 30 dB compared to open-frame units.

Together, these systems enable silent diesel generators to operate with library-level quietness while delivering full power output.

Energy Efficiency and Long-Term Operational Cost Savings

The newer quiet versions actually burn around 15 to 20 percent fewer gallons for every kilowatt hour compared to older equipment. Plus, those engines that meet Tier 4 standards slash soot particles by almost 90 percent. Companies typically pocket about eighteen grand on fuel costs alone over ten years, not counting roughly twelve thousand dollars saved from dodging noise complaints and associated fines according to the Energy Cost Index report from last year. And let's not forget about those variable speed cooling fans either. They work wonders when machines aren't running at full capacity, which cuts down on heat buildup and wasted electricity across the board.

Real-World Example: Hospital Backup Power With Minimal Disruption

When a Tier 1 trauma center upgraded to silent diesel generators, emergency protocols continued uninterrupted during outages, with sound levels remaining below 55 dB in patient wings. Staff reported zero disruptions to telemedicine consultations or MRI operations—a stark contrast to their previous 82 dB generator that forced temporary wing evacuations.

Critical Specifications to Compare in Silent Diesel Generators

Power Output (kW/kVA) and Matching Generator Capacity to Load Demands

Getting the right power output means looking at both the running watts and those extra starting watts needed when equipment kicks on. Things like heating systems or important medical gear can really spike power needs at startup sometimes needing two to three times what they normally draw. If we go too small, there's real risk of everything shutting down mid-use. But going way overboard just burns through more fuel than necessary. Industry folks have found that getting the size wrong typically adds around 18 to 22 percent to yearly costs. A good rule of thumb is to look for generators that offer about 10 percent extra capacity beyond what's needed at peak times. This gives enough breathing room without wasting money on unnecessary power reserves.

Fuel Efficiency, Consumption Rates, and Extended Runtime Considerations

Silent diesel generators today can reach fuel consumption rates between 0.3 and 0.5 liters per kilowatt hour thanks to better combustion systems and intelligent idle management features. Take a standard 100kW generator running for about 8 hours each day as an example. Over time, these units consume roughly 72 to 120 liters of fuel daily. When we look at the bigger picture, this efficiency saves around $740,000 over a decade when compared with older, less efficient models according to Ponemon's 2023 report. For reliable operation during extended power failures, it makes sense to go for fuel tanks that hold at least 24 hours worth of supply plus some kind of built-in fuel monitoring system. This ensures the generator keeps running without interruption even when nobody is around to check on things.

Decibel Levels: Defining "Silent" Based on Industry Standards

"Silent" classifications require noise levels below 75 dB(A) at 7 meters—comparable to urban traffic—versus standard generators‘ 90–110 dB jackhammer-like output. Leading models achieve 65–68 dB through triple-layered acoustic enclosures, tuned exhaust resonators, and vibration-isolated engine mounts.

Data Insight: Modern Enclosures Reduce Noise to 65–75 dB Range

| Feature | Traditional Generators | Silent Diesel Generators |

|---|---|---|

| Avg. Noise @7m | 90–110 dB | 65–75 dB |

| Enclosure Type | Open-frame | Sound-attenuated steel |

| Typical Applications | Remote construction | Hospitals, residential |

Tested models show 72 dB output under 80% load—meeting OSHA‘s 8-hour exposure limit of 85 dB with a 13 dB safety margin.

Assessing Build Quality and Advanced Noise Suppression Features

Soundproof Enclosures and Integrated Vibration Dampening Systems

Silent diesel generators today incorporate several layers of engineering tricks to cut down noise levels way beyond what most competitors offer. The steel covers are lined with mineral wool that soaks up around 85% of the mechanical noise right where it starts. Meanwhile, mounting the engines on rubber helps knock out about 40% of those annoying vibrations that standard models just let pass through. When tested according to ISO standards, these quiet machines typically measure under 74 decibels at seven meters distance when running at full power. That kind of performance makes all the difference for places located close to office buildings or neighborhoods. Take hospitals as an example. Many medical centers need their backup power sources to stay below 60 dB because loud noises can really interfere with recovery processes and disturb patients who are trying to rest.

Durability of Materials: Steel vs. Composite Housing for Silent Diesel Generators

Heavy-gauge steel housings offer 12–15 year lifespans in coastal environments when galvanized. However, fiber-reinforced composite alternatives are gaining traction, weighing 22% less while matching steel‘s corrosion resistance according to 2023 ASTM stress tests. In food processing plants facing daily washdowns, composite housings resist chemical degradation three times longer than powder-coated steel.

Weather Resistance and Best Practices for Outdoor Installations

Equipment with an IP rating of at least 54 keeps out dust and moisture even when dealing with heavy rains or sandstorms. For best protection against flooding, install these units about six inches off the ground where water tends to collect. Make sure those exhaust vents face away from the direction most wind comes from, and don't forget to ask for UL certified protective coatings if the installation site gets really cold (-40 degrees Fahrenheit) or extremely hot (up to 122 degrees). Real world testing back in 2022 found that when everything was set up correctly according to these guidelines, there were roughly two thirds fewer maintenance issues caused by bad weather conditions during a five year period.

Maintenance and Long-Term Reliability of Silent Diesel Generators

Recommended Servicing Intervals and Filter Replacement Schedules

Regular maintenance makes all the difference when it comes to keeping equipment running at peak performance. Most manufacturers suggest getting service done around every 500 operating hours or within 6 to 12 months, whichever comes first. This usually means changing the oil, swapping out air filters, and checking the fuel system for issues. When folks skip these regular checkups, they're looking at about a 15% drop in efficiency plus components wearing out faster than normal. Take oil changes for instance – putting them off just leads to more engine wear over time. And those dirty air filters? They put extra stress on cooling systems that nobody wants. The situation gets even trickier with Tier 4 compliant machines since they need special attention to their particulate filters roughly every 2,000 hours if we want to stay within emission regulations.

Common Challenges: Cooling and Exhaust System Performance

When machines get enclosed for noise reduction, they tend to trap heat inside too. The temperature inside these soundproof boxes goes up anywhere between 8 to 12 degrees Celsius compared to regular open frame setups. That extra warmth puts serious strain on cooling systems like radiators and pumps which weren't designed for such conditions. Another common problem comes from those insulated exhaust manifolds. Small cracks that nobody notices at first can leak harmful gases while also making things louder by around 10 to 20 decibels. Maintenance teams have started doing infrared scans every three months now. These checks catch overheating spots early enough so breakdowns don't happen during production runs when everything matters most.

Are Sealed Silent Diesel Generator Units Harder to Maintain?

Enclosed generator designs typically hit around 65 to 72 decibels at seven meters distance, which is great for noise control but comes with some headaches when it comes to regular maintenance work. Technicians often find themselves wrestling with vibration resistant panels and acoustic insulation just to replace something simple like fuel injectors or alternators. On the bright side though, newer modular systems have made things much easier in recent years. According to field reports, about 45 percent of techs say they finish their maintenance jobs about 25 percent quicker now thanks to those convenient tool free access points built into modern units. And let's face it, the extra effort pays off handsomely in the long run. Sealed generators suffer roughly 70 percent less damage from rain, snow, and other weather conditions compared to older open frame models sitting out in the elements.

Ensuring Compliance with Safety and Environmental Standards

Meeting OSHA Guidelines and Local Noise Ordinances

Quiet diesel generators need to stay under OSHA's 90 dB noise limit for eight hour shifts according to their 2024 guidelines. Most newer models run around 65 to 75 dB, which is actually pretty quiet compared to what's allowed. Cities tend to get even pickier about noise in business areas though, so anyone running these generators should check exactly what their local rules say before setting one up. Take hospitals for instance. When they install emergency power systems, they have to satisfy not just worker safety regulations but also those annoying neighborhood noise laws or risk getting hit with some serious penalties from city officials.

Emissions Compliance: Tier 4 Standards and Diesel Particulate Filters

Today's quiet diesel generators actually follow those strict Tier 4 Final emission rules from the EPA. These new standards cut down on particulate matter by around ninety percent when compared to older models back before Tier regulations were introduced in 2024. The machines come equipped with built-in diesel particulate filters that trap all that nasty exhaust soot. There's also something called selective catalytic reduction systems working behind the scenes to bring nitrogen oxide levels way down. Beyond just ticking boxes for regulatory compliance, these tech upgrades really do help companies move toward greener operations. And let's face it, nobody wants to deal with potential fines that can hit as high as thirty-seven thousand five hundred dollars each time there's a violation according to the Clean Air Act provisions.

Fire Safety Clearances and Proper Ventilation Requirements

Most manufacturers recommend keeping at least three to five feet of space between generators and walls or flammable materials to avoid overheating issues. When it comes to ventilation, proper systems need to handle both exhaust dispersion and overall air movement, particularly important when installing inside buildings. Outdoors? Look for housing that stands up to weather conditions and mount equipment high enough to stay dry during heavy rains or floods. Never forget to check what the manufacturer says in their safety guide alongside whatever local fire regulations apply. Install something wrong and not only does the warranty disappear, but companies could face serious legal consequences down the road.

FAQ Section

What makes silent diesel generators different from regular generators?

Silent diesel generators are designed with acoustic enclosures, vibration dampeners, and exhaust mufflers, reducing noise levels significantly compared to regular generators.

Are silent diesel generators more fuel-efficient than traditional models?

Yes, they generally burn about 15 to 20 percent less fuel per kilowatt hour compared to older models and can result in substantial long-term cost savings.

Do silent diesel generators conform to noise and environmental regulations?

Yes, they meet OSHA's noise guidelines and adhere to Tier 4 emissions standards, reducing not only noise but also particulate emissions dramatically.

How often should silent diesel generators be serviced?

Manufacturers usually recommend servicing every 500 operating hours or every 6 to 12 months to maintain optimal performance.

Table of Contents

- Why Silent Diesel Generators Matter in Commercial Settings

- Critical Specifications to Compare in Silent Diesel Generators

- Assessing Build Quality and Advanced Noise Suppression Features

- Maintenance and Long-Term Reliability of Silent Diesel Generators

- Ensuring Compliance with Safety and Environmental Standards

- FAQ Section